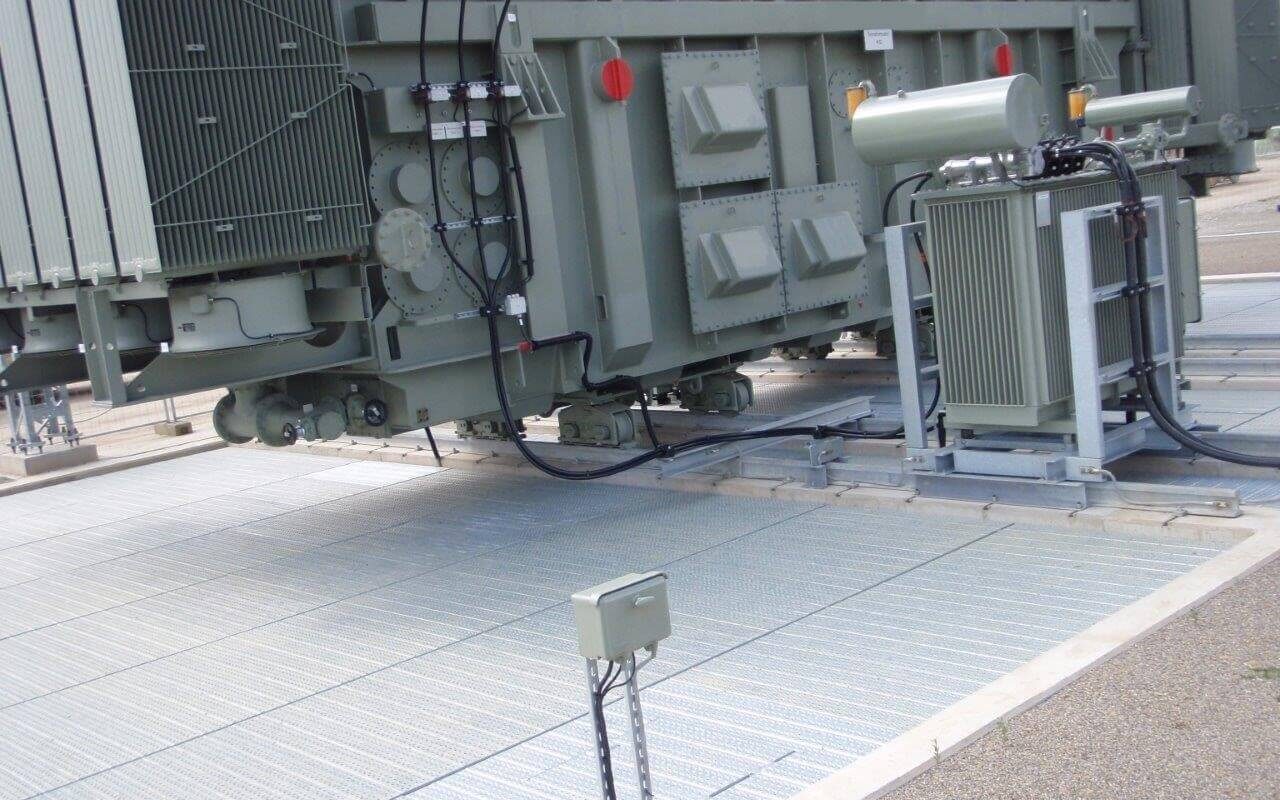

EXTICOVT CCF™ covers and the EXTICOV CCF™ range were specifically designed to meet the needs of the French electricity industry and addresses the risks associated with hydrocarbon pool fires for electrical transformers.

Characteristics of EXTICOVT CCF™ covers

The cover consists of special 20/10 steel fire suppressing baffles placed in metal frames. These are installed at the top of the pit on specially designed angles.

This system replaces the traditional pebble bed on gratings, an old system that is difficult to clean in the event of an oil spill, difficult to measure in terms of reliability and sometimes dangerous for operators: slippage, instability, explosion, reignition, pebbles to be depolluted, etc.

The whole unit is made of hot-dip galvanised steel in accordance with the ISO EN1461-2002 standard.

The baffles are specially engineered to accelerate the passage of burning oil into the pit under the baffles. Once the hot oil is “trapped” in the pit, the fire almost instantly self-extinguishes due to insufficient air penetration and oxygen depletion.

Moreover, because the suffocation phenomenon is very rapid, the temperature rise inside the pit is low and thermal runaway that could lead to the acceleration of the fire’s propagation is made almost impossible. The device therefore acts passively and simultaneously on 2 of the 3 components of the fire triangle in a simple yet effective way.

System load-bearing capacity from 250 kg/m² to 500 kg/m² (distributed load) depending on your requirements.

The whole system is connected to the ground (angles, frames, gratings)

Model tried and tested for 20 years, compliant with NFC13200, tested at the CNPP national fire laboratory.