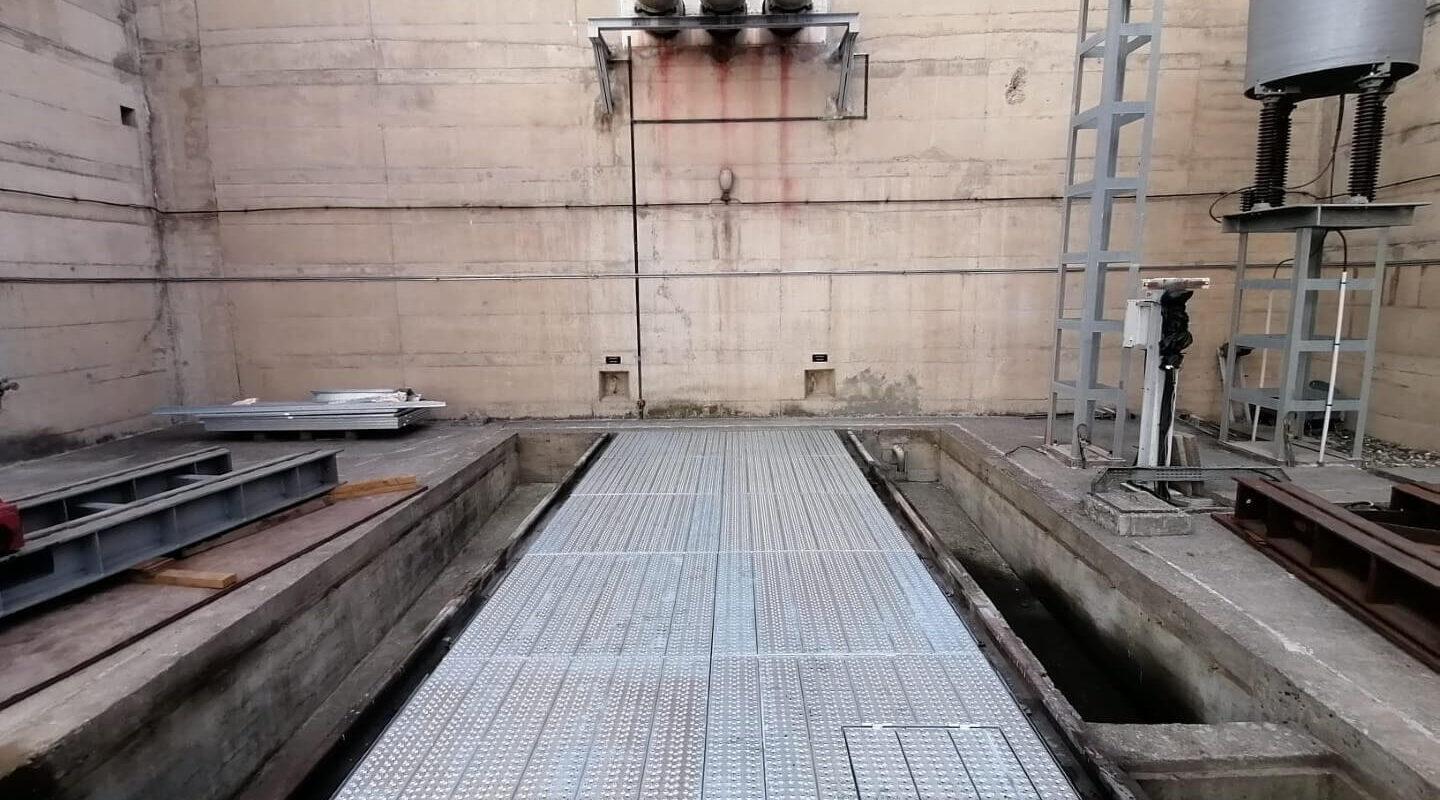

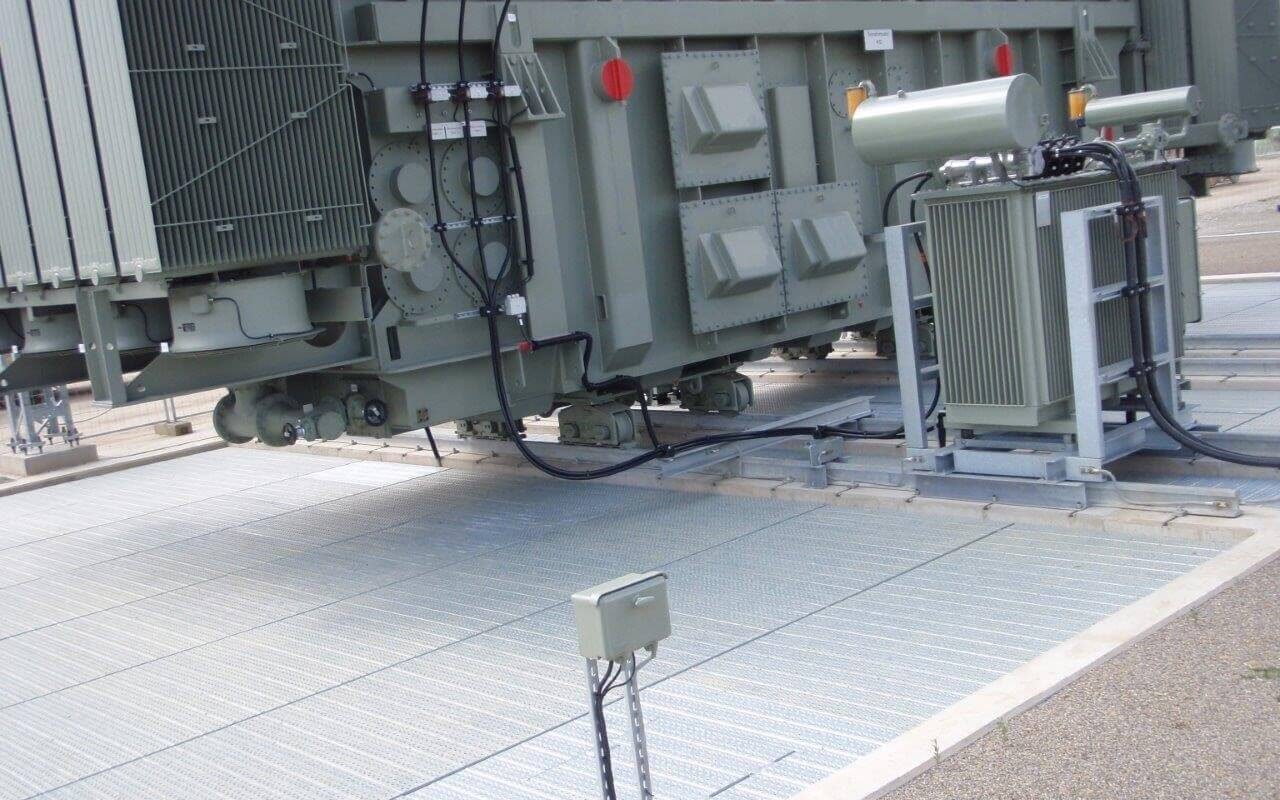

EXTICOVT-LHD® industrial fire extinguishing gratings are directly derived from the Oil & Gas off-shore transportation sectors and the substations of energy production and distribution companies of the world.

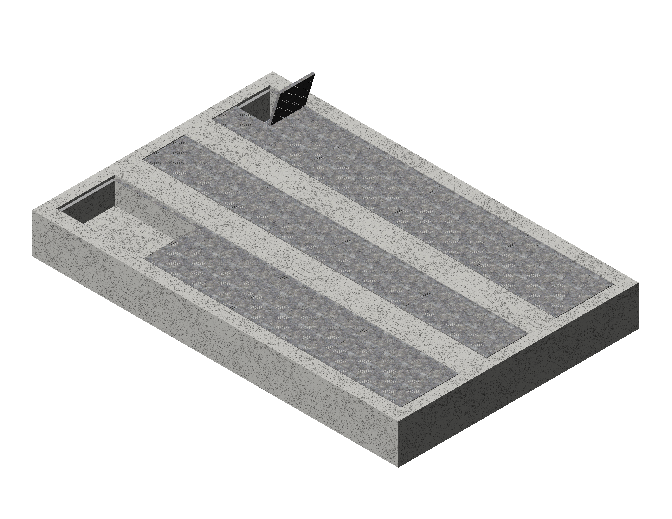

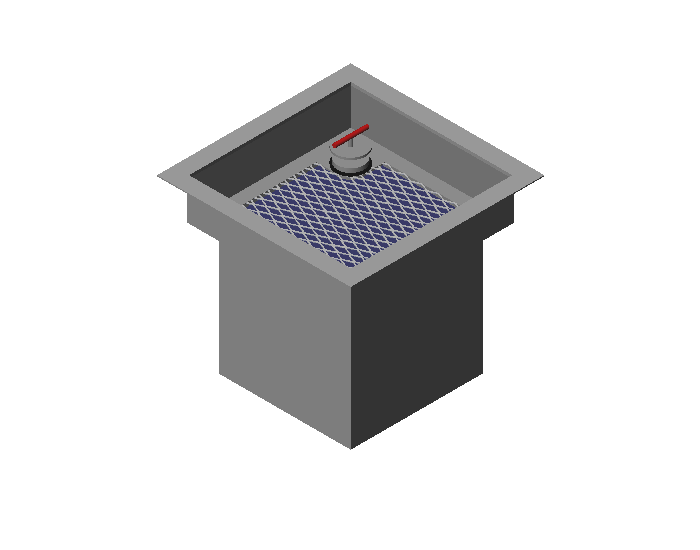

The EXTICOV-LHD® cover is a galvanised sheet metal floor with a perforated surface structure.

It is made from U-shaped sheet steel, 2 or 3 mm thick, depending on your need for strength. These various elements are welded into panels. The delivery in panels avoids time-consuming screwing of elements during assembly. This means installing and maintaining the retention pits will be a much quicker and cheaper task.

The EXTICOV-LHD® fire extinguishing cover owes its fire suppressing effect to the perforated surface structure, which only allows a reduced supply of oxygen to the fire area.

The fire area is consequently deprived of a significant amount of oxygen, resulting in an extremely under-ventilated fire. Despite this reduced airflow, oil escaping from the transformers in the event of damage can flow freely and quickly into the retention tank underground (600 litres/minute over a surface area of 1000 x 1000 mm)

Advantages compared to other traditional fire extinguishing covers:

- Tested by several laboratories for fire resistance,

- Greater drainage volume due to the structure of the cover,

- Reduced assembly and disassembly time: the grating is part of the floor and is a one-off grounding operation,

- Reduced dead weight and therefore reduced cost of supporting structures,

- High passive safety for maintenance and service personnel, non-slip surface,

- Less risk of clogging the system with leaves or organic residues,

- Easy to create access hatches.